Hi, I'm the G70

LET'S BREW BIG

TOGETHER.

HI, I'M THE G70. LET'S BREW BIG TOGETHER.

G70

This is our ultimate brewing system with a gigantic 70L (18 US Gal) capacity, allowing you to create 58L (15 US Gal) batches of beer at a time. The perfect match for experienced brewers, which has built-in wireless connectivity, so you can connect to the Grainfather App to access brewing tools, recipes, and calculators.

Pairs with:

Go on, i love a

challenge

challenge

Go on i love a

challenge

challenge

challenge

challenge

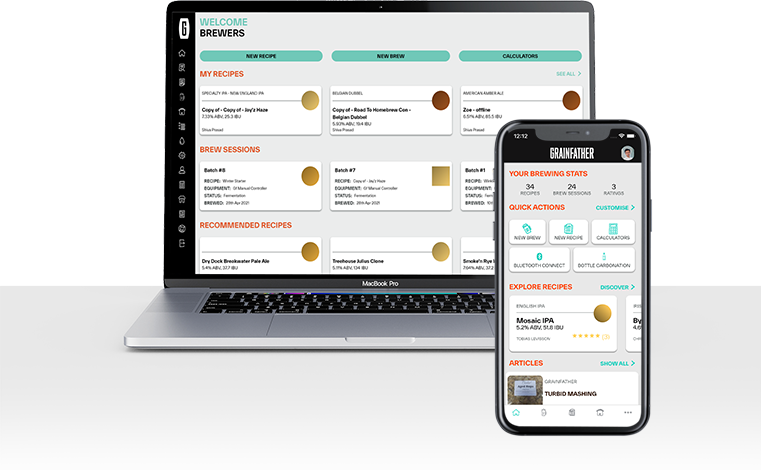

CONNECT ME TO THE APP FOR THE ultimate experience

The Grainfather App is free to download and available to both Android and Apple users. Connect any G SERIES product to the app via your mobile device and brew more confidently with our step-by-step system.