G70: NEUTRAL SPIRIT DISTILLATION

Reflux distillation produces a neutral spirit, such as Vodka or a neutral base spirit for flavouring. You can also infuse your neutral spirit with botanicals in a few more steps to make spirits such as Gin.

To distill neutral spirits on the G70 Brewing System, you’ll need the Grainfather Distilling Lid, T500 Reflux Condenser, Attachment Kit, and a few more pieces of equipment you may already be using in your brew house. Be sure to gather all equipment and ingredients required and make the wash in advance.

STEPS

1. Prepare your G70 for Reflux Distilling

Remove Sight Glass

Remove the sight glass opposite the recirculation arm to avoid pressure build-up that may cause leaking from the top vent hole. You may skip this step if your unit does not have a sight glass opposite the recirculation arm.

Follow these steps to remove the sight glass:

- Using an adjustable spanner (wrench), remove the hex bolt at the bottom of the sight glass inside the bolder unit and carefully remove the sight glass.

- Keep the hex bolt but remove the O-ring.

- Locate the G70 spares pack and find the blank hex cap.

- Keep the hex bolt in place. Put one of the flat seals (supplied with the distilling lid) over the threaded section protruding from the boiler. The seal should be between the outside of the bolder wall and the blank hex cap.

- Tighten the blank hex cap, so the hole is sealed. Do not over-tighten.

- Fill the unit with 15L (4 US Gallons) of water to perform a leak test on the blank hex cap.

- Remove the water if there is no leaking.

Attach the recirculation elbow seal TO ENSRE NO VAPOUR LOSS

- Use an adjustable spanner (wrench) to remove the hex bolt inside the boiler.

- Keep the hex bolt and retention clip in place.

- Take one of the flat seals supplied with the distilling lid and place this on the threaded section protruding from the boiler. The seal should be between the outside boiler wall and the external recirculation pipe connection.

- Re-tighten the hex bolt, ensuring it is tight enough to seal properly but not over-tightened.

Fill the G70

- Ensure the hop filter is in place.

- Add Wash – Max volume 65L (17.2 US Gal).

- Add 10 ceramic boil chips to the bottom of the unit.

- Add distilling conditioner/antifoaming agent to the wash (follow the instructions on the bottle

2. Assemble the Distilling Lid, T500 Reflux Condenser, and Attachment KiT

Distilling Lid

- Place the distilling lid (with the clamp removed) onto the top of the unit. It should sit firmly in place.

- Fit the clamp around the lid and the rim of the unit. Fasten the clamp by connecting the two ends and closing the lever. Tighten as needed by adjusting the lever screw when the lever is open.

Attachment Kit

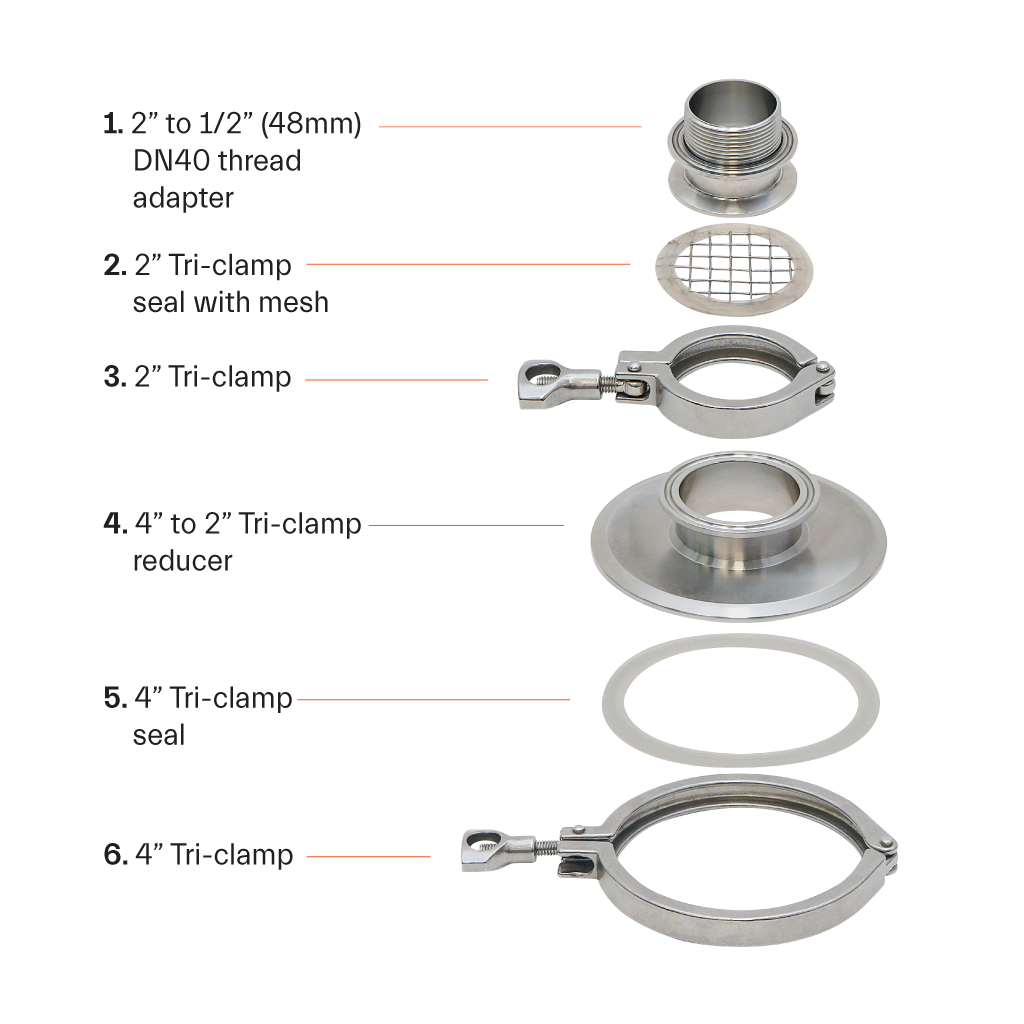

- With the T500 Reflux Condenser turned upside down, thread the 2” to 1/2” (48mm) DN40 thread adapter (1) to the bottom of the T500 Reflux Condenser. Place the 2” tri-clamp seal with mesh (2) onto the flange on the 2” to 1/2” (48mm) DN40 thread adapter.

- Place the 4” to 2” tri-clamp reducer (4) on top of the 2” to 1/2” (48mm) DN40 threaded adapter, ensuring the seal remains in place. Connect using the 2” tri-clamp (3).

- Place the 4” tri-clamp seal (5) onto the flange of the distilling lid and place the T500 Reflux Condenser on top of the unit, ensuring the seal remains.

- Secure the T500 Reflux Condenser by using the 4” tri-clamp to join the 4” to 2” tri-clamp reducer (4) to the distilling lid.

3. Set up the T500 Reflux Condenser

- Ensure you are close to a sink with drainage and access to water. You will also need a flat surface for a collection jug to sit next to the unit.

- To calculate the minimum volume of the collection jug, use the formula below:

(Wash volume in (L) * wash ABV) + (Wash volume in (L) * 0.01) = minimum volume of alcohol collection vessel

Connecting the water hoses

Refer to diagram below.

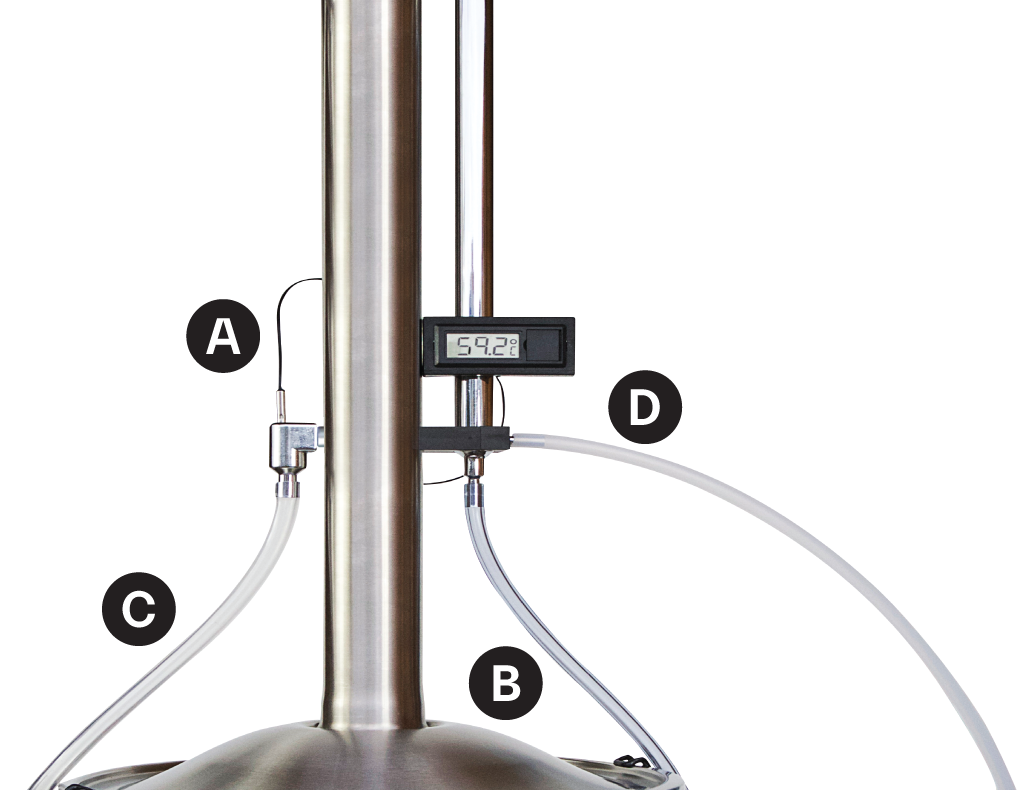

- Connect the long, thick, clear tube to block outlet C. The water from this tube will flow into your sink.

- Connect the short, thin, clear tube to make the top loop connection E.

- Connect the thin clear tube on the water inlet B to your tap. Water will flow from your tap (via the adaptor) into the condenser.

- Connect the white tube to the spirit outlet D. The distilled alcohol will flow from here to your collection jug.

- Ensure the tube is not submerged in the distillate. Otherwise, the boiler may implode. You should see drops of distillate falling into your collection vessel.

Connecting the Thermometer (Sold Seperately)

Refer to diagram below.

- Place the battery in the thermometer.

- Turn the thermometer on. Set to Celsius or Fahrenheit.

- Mount the thermometer in the mounting bracket provided. Clip the panel onto the condenser near the bottom.

Fitting the Sensor Probe

Refer to diagram below.

- Fit the stainless-steel sensor probe into hole A.

- Use a wire tie to tidy up loose wiring.

Water Flow Regulator (sold separately)

Using a water flow regulator allows for optimum water control and prevents pressure and temperature fluctuations that can lead to issues with the quality of your distillate.

Purchase a Still Spirits Water Flow Regulator (sold separately) at your local homebrew shop.

Connecting to a Tap

- Fit the water flow controller to your tap/faucet.

- Shut the water flow valve completely.

- Connect the long thin tube to the flow controller.

- Place the long thick tube into the sink or drain.

- Place the white alcohol outlet tube into the collection jug or vessel. Position the tube so it cannot be submerged in the distillate to avoid pressure build-up. Otherwise, the boiler may implode.

4. Using the T500 Reflux Condenser

Setting the Power Control

Put the unit into Power control mode by pressing ‘set’. Select the power control mode in the menu. Use the arrow to set the unit to 100% heating until the boiler reaches 75°C (167°F).

Turn on Water

Adjust the flow to between 0.4-0.8 L per min using either your water flow regulator.

ADJUSTING THE POWER CONTROL

Depending on your ground water temperature you may need to increase the amount of water being used or once the boiler reaches 85C you can reduce the Power control down.

Note: It is recommended if you are using the G40 in 10Amp mode to keep the Power control at 100%

Monitor the Temperature

- The water out temperature from the column will slowly rise, and spirit should start to appear when the temperature reaches 50°-55°C (122°-131°F).

- Collect and discard the first 100ml (33.8 US fl oz).

- Continue to monitor water flow and temperature. Adjust the water flow so that a column temperature is between 55°-65°C (122°-149°F).

- Collect spirit until you have Wash vol (L) * Wash ABV = minimum volume of alcohol collection vessel

- Start collecting 100ml samples and measuring these with an alcometer.

- When the ABV of the distillate drops below 90%, stop the distillation, or if the distillate slows to 1 drop every 5 to 10 seconds, all the alcohol has been distilled, and the boiler can be turned off.

Clean Up

- Ensure the white distillate out tube is not submerged in the distillate.

- Turn off the unit and disconnect the power outlet.

- Turn off the cooling water supply.

- Allow the depleted wash to cool to a safe temperature before emptying. The distillate liquid will be dangerously hot.

- Remove the T500 Reflux Condenser and distilling lid assembly. Rinse off all wash and debris. Retain the ceramic boil enhancers for the next distillation run.

- Run water through the condenser to rinse the saddles every 5 to 10 distillations. Replace saddles if the distillate starts to taste earthy.

- For a thorough clean, every 20 distillations or so, rinse your column with a citric acid mix. Add 2 tsp citric acid to 1L (1 US qt) of water. Then flush with water 2 to 4 times to rinse out the acid.

Legal Considerations

Distilling at home is legal in New Zealand. Check the laws in your country or state before you get started.